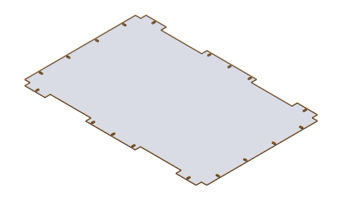

Deckplate

Initial Analysis and Measurements:

- Measured the existing deck plate from a previous design (36″ x 24″ x 1/8″ thick).

- Added 1″ x 1″ square cutouts at each corner to align with the chassis.

- Included 1/4″ slot screw clearances on all four sides to maintain deck plate integrity.

Design Iteration:

- Developed the first design version in SolidWorks to analyze and plan adjustments based on measurements.

Material Selection:

- Defined requirements for the deck plate material, including resilience to vibrations, G-forces, weight capacity (35 lbs), speed (0-5 mph), and minimal deflection (< 1/4″).

- Selected aluminum 5052-H32 for its lightweight, strength-to-weight ratio, impact resistance, and heat dissipation properties, ideal for maintaining stability, safety, and electronic component protection.

Testing for Durability:

- Conducted load testing by placing a 20-lb cinder block on the deck plate to assess weight support and rear down-force, enhancing rear traction via Finite Element Analysis.

- Strategically positioned the electronics suite at the front of the vehicle for optimal balance and intelligent function.

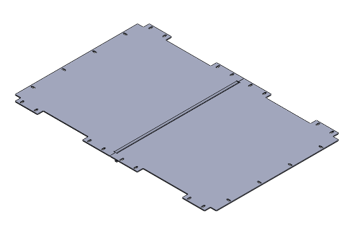

First Product

Final Product

Redesign and Modifications:

- Split the deck plate into two symmetrical pieces with a 90-degree bend to increase stiffness and load support.

- Added cut-outs on each side to allow mounting brackets to sit flush with the chassis, enhancing modularity and ease of service.