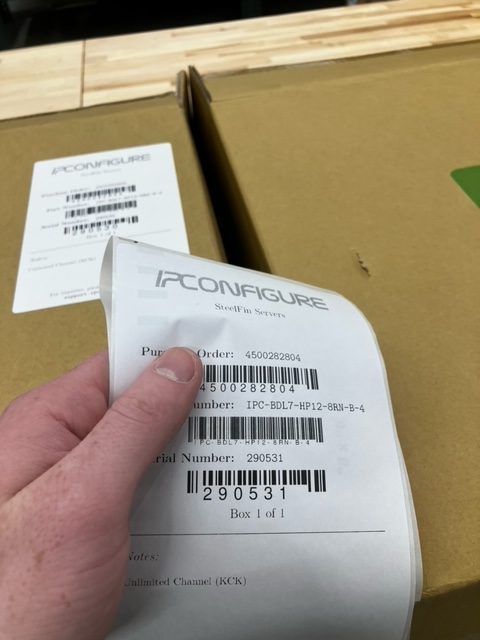

My past two reflection papers have covered the mastery of assembly, troubleshooting, and imaging. I wanted to cover some of the tasks I have been involved with that weren’t directly stated in my job title. Firstly, boxing and ‘palleting’ servers. Though a seemingly benign task, I have a newfound respect for those who work in the shipping/receiving industry. When we complete an order, fully imaged, stickered, and quality assured, the next task is to place all the servers back into the original boxes they came in. Before this, however, we must place special packing stickers onto each box, each with a unique serial number. This is the same serial number that is on each server. We then have to match each server to their specific box, and begin the process of repackaging them. This is one of the more tedious tasks, as after filling the chassis with metal and wires, they can become fairly heavy and awkward to manipulate. When you have to put Styrofoam and plastic wrap on and cram them back into a box, it becomes especially irritating sometimes. Once an entire order has been properly ‘boxed’, an assembler must go through and place the proper peripherals, including keyboards, mice, monitors, antennas, or power cables within the box. After that, another assembler must go behind and confirm that the serial numbers on the box and the server match, as well as there being the proper cables and peripherals in the box, signing a packing sheet and stuffing it into the box. (With all the stuff already in there! Tight fit!) Finally, we place all the boxes onto a singular pallet, playing an extreme game of Jenga, putting wrap and plastic straps on the pallet. We then take the shipping company’s labeling stickers and place them on the pallet, including their packing slips. It is a process!

I know most of my reflections have been about the job itself, I think one subject to mention is the CEO. The CEO, Chris Uiterwyk, is one of the humblest men I have ever met. He is compassionate, cares for his employees, and doesn’t command respect, rather earns it through his actions. I thought it necessary to say something about him in my reflection, as he and his policies has made the IPconfigure experience very memorable. For example, he explained one day how much waste we have at our company. Computer parts, chairs, office supplies, he said “If it’s in the trash, or if it’s going in the trash, its yours.”. Essentially, anything that’s going to the dumpster is finders keepers! The chair I’m sitting in writing this was going to the dumpster because they didn’t need it. The picture below displays this “waste not want not” mindset. I’ve been building a server, and most of the components in the build are actually parts that were out of warranty, with nothing wrong with them!

Here’s a finished pallet, you can’t see it directly, but if you look to the left of the box on the top,

you can kind of make out the packing slip. This is usually a process, the saran wrap has to be

done slowly to ensure it’s taut, and the straps tight enough so the boxes don’t fall off.

These stickers have serial numbers that match the ones we automatically assign the servers in the

OS.

Here’s all the boxes laid out, before stickering and actual boxing.

Here’s my server I’ve been working on. It’s been a process, but I put moxprox on it, a

virtualization OS. I can, from my browser, access the server when it’s on and use virtual

machines. If I wanted to, I could use secure shell, (SSH), and get into it while on the go from a

laptop or phone.