Risk Management Recommendations – MPH 632

- Scenario

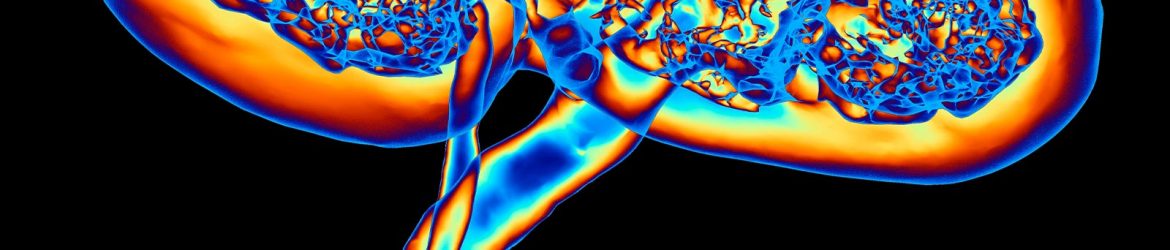

- A mid-size city in the Southeast (approximate population 744,000) has several major chemical production facility employers located within 10 miles of the city center. Each facility employs approximately 6,500 workers. One of the chemical producers makes toxic carbamate pesticides using intermediates such as highly toxic Methyl isocyanate (MIC; e.g. Bophal India catastrophe). The production process for carbamates is very complex and requires careful oversight and monitoring. This facility uses and stores very large quantities MIC such that they keep approximately 1 full year’s supply in their inventory. Part of the production process involves high temperatures and can produce explosive and flammable gases if not carefully monitored and controlled. The process also produces still bottoms and sludge that also must be discharged and disposed. The raw materials and end products are also shipped into and out of the production facility via rail car. The rail lines used carry passenger and cargo trains throughout the day and are within 5 miles of the downtown area. This facility has public health, occupational health, and ecological health hazards that must be managed.

- Background

- Given the certain scenario about a rail company hauling cars full of Methyl Isocyanate (MIC) — the same substance that devastated Bhopal, India in 1984 — through a city limit, I was to construct risk management recommendations and solutions to limit the dangers present within the given scenario. I formulated a total of seven safety suggestions and placed them in order of priority. These suggestions stem from industrial changes to infrastructure changes to ensure the safety of the city’s population.

- Key study question(s) and Methods

- For this Practice Lab, the main focus was formulating and recognizing the hazards within the scenario. Some of the questions that I had to analyze were: What chemical was being used? How does the chemical affect biological and environmental health? What can be changed to limit hazards at a local, regional, and global level?

- Proposed Recommendations and Findings

- Moving plants further than 10 miles from the city center.

- Proper safety and accident prevention protocols ensured in the production of harmful chemicals such as methyl isocyanate (MIC).

- If a factory is unable to properly relocate to a remote location, mandatory change of the storage facility to more rural locations.

- Seeking out alternative forms of pesticides that may not be as deleterious to human health and alternative ways to produce pesticides without the need for high temperatures / high pressures.

- Create new rail lines that do not enter the city sections.

- Implement safety systems that ensure the safe and environmentally friendly disposal of waste materials.

- Ensuring that rail cars are well supported to prevent BLEVE (Boiling Liquid Expanding Vapor Explosion) accidents.

- Public health significance

- Albeit a scenario, these types of situations occur. As a future public health officer, it is my duty to analyze and identify potential hazards present within scenarios like the one given in Practice Lab 2.

A PDF version of the Practice Lab 2 can be found below.

A9-MPH-632