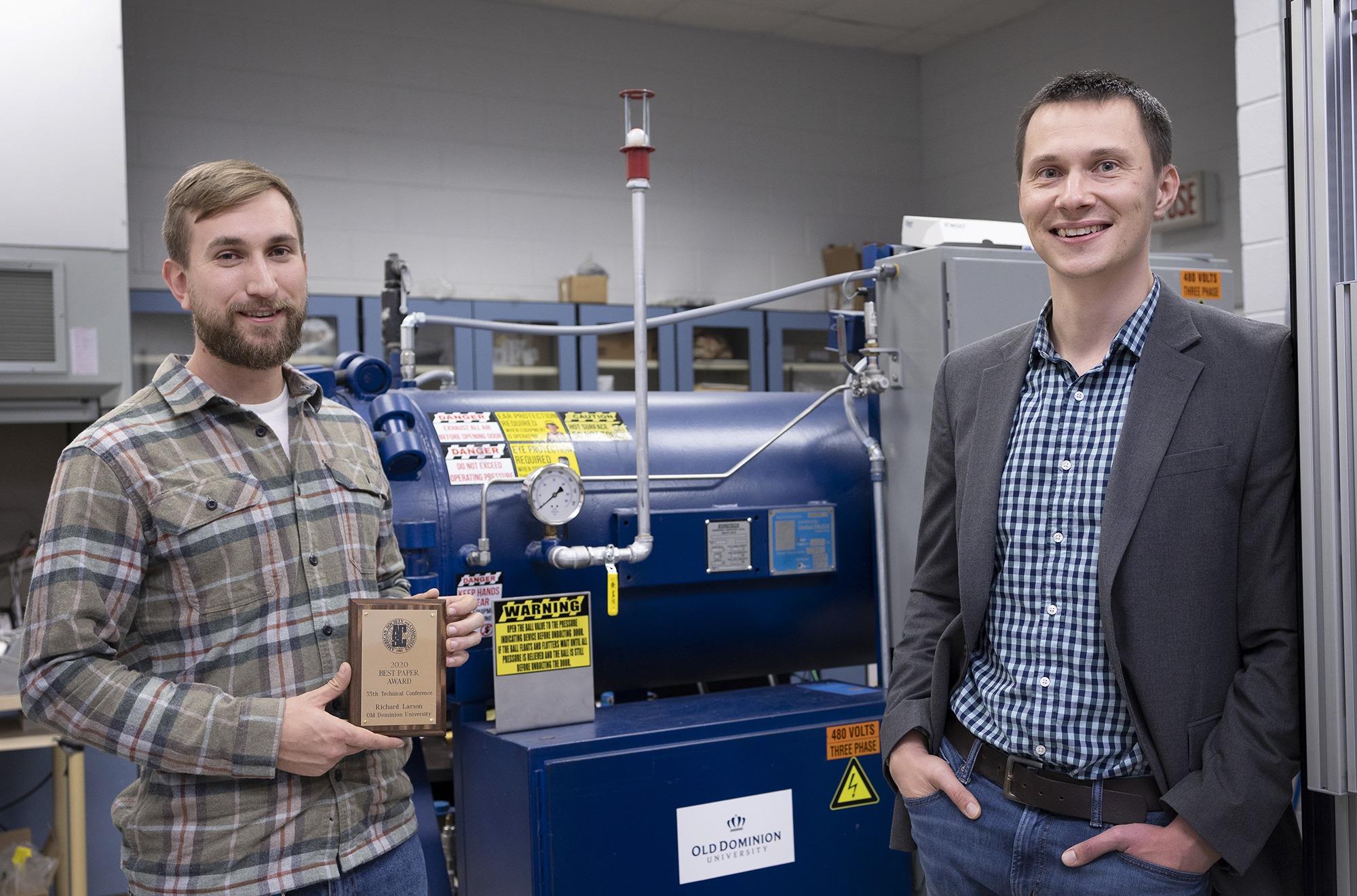

Oleksandr Kravchenko, Ph.D., an associate professor in Old Dominion University’s Department of Mechanical and Aerospace Engineering, has received a $450,000 grant from the Air Force Office of Scientific Research (AFOSR) to develop deployable thermoplastic carbon fiber composite booms for CubeSats—small satellites used in space missions.

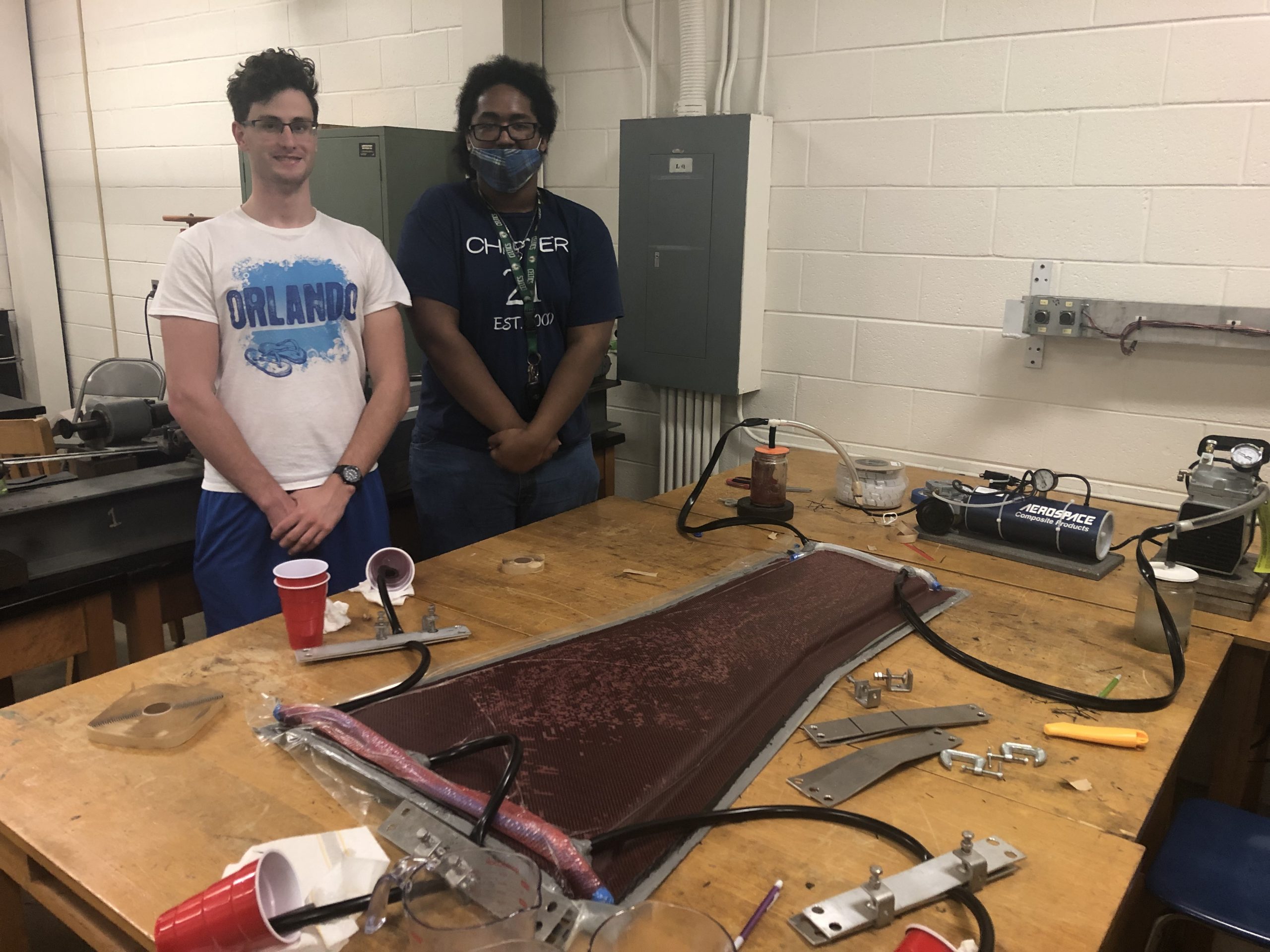

As director of ODU’s Composites Modeling and Manufacturing (CMM) Group, Kravchenko will lead a team of engineering students and faculty in advancing this innovative technology.

The three-year project, led by ODU in collaboration with the University of Washington (UW), focuses on developing novel lightweight, foldable arms known as deployable booms that support and extend antennas once the CubeSats are in orbit. The proposed boom will utilize tow-steered carbon fiber and space-grade thermoplastics for improved thermo-mechanical stability and rapid manufacturing. The project will serve as a research demonstrator for the next generation of deployable structures in CubeSats.

“We’re trying to build more resilient structural booms: longer, stiffer, and more resistant to thermal fluctuation by using advanced manufacturing and materials,” Dr. Kravchenko said. “The success of the project requires testing under conditions expected during launch and in space environments, so we use extensive qualification and physics-based simulations to predict how manufacturing will impact the mechanics of this boom.”

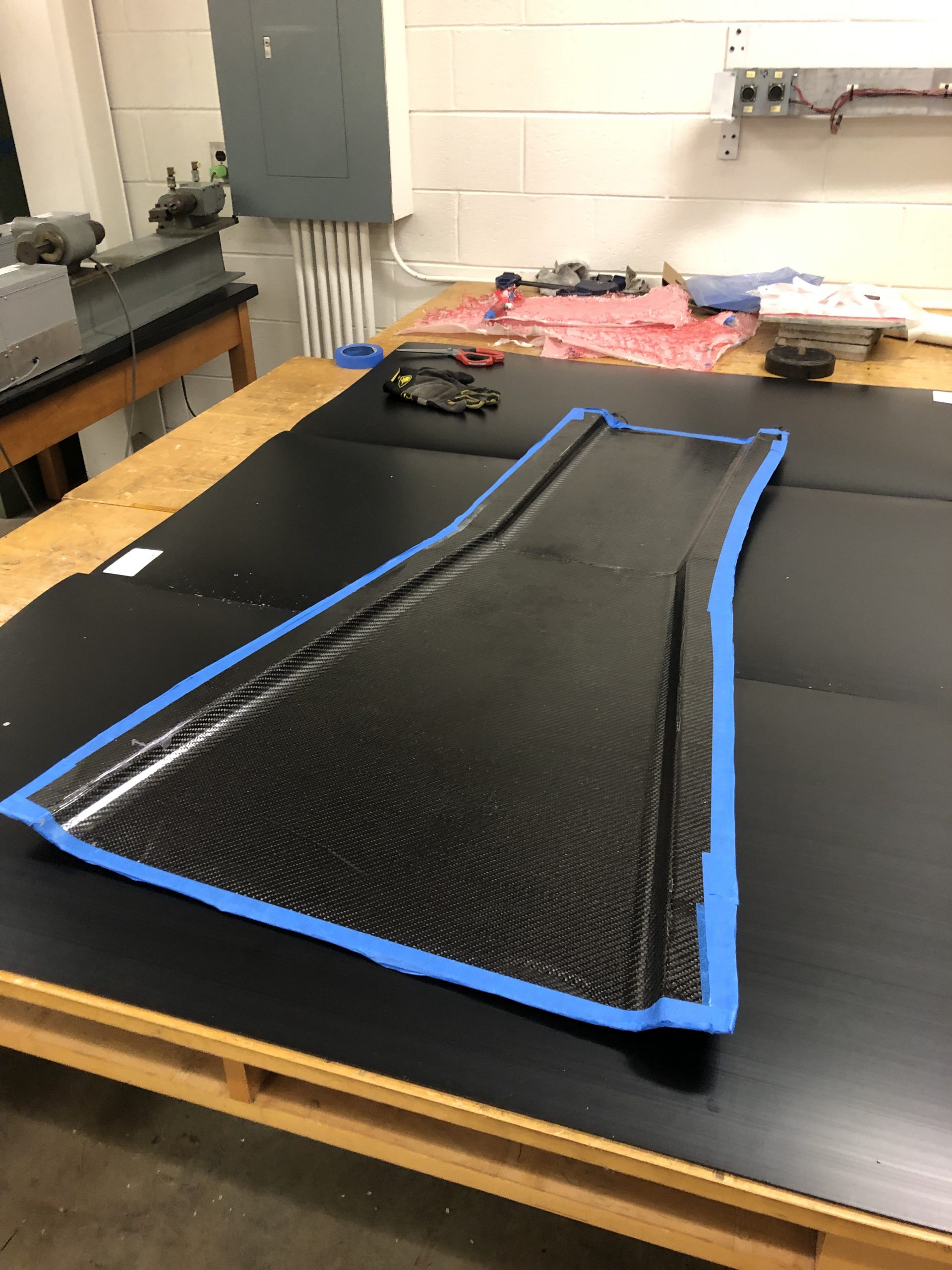

In collaboration with UW, the project uses tailored placement of thin carbon-fiber thermoplastic strips using an advanced manufacturing technique called Automated Fiber Placement (AFP), in which a robotic arm lays down narrow fiber strips in precise patterns. The fiber sheets are then formed into booms using heat and pressure through a process called thermal stamping. The process eliminates the need for large, expensive autoclaves traditionally used to cure aerospace composites.

“Traditional composites have been used in booms for quite some time; they’re not new,” explained doctoral student Jimesh Bhagatji. “However, our work brings a new ‘flavor’ by using thin-ply composites and tow steering in designing the next generation composite booms. This allows for tailored fiber angles throughout the structure to achieve the desired mechanical behavior. Once we determine these parameters using simulation tools developed in our group, the AFP machine will be able to produce them.”

Graduate student Christopher Schappi has been involved in ODU CubeSat projects since his freshman year. “I worked on CubeSat projects at ODU for a few years during my undergrad, and composite materials was the next thing I wanted to learn about,” he said. “Through this, I learned composite fabrication and testing. Currently, I am working on finite element analysis of deployable structures and refining these models, so we can accurately predict what we see in the actual application.”